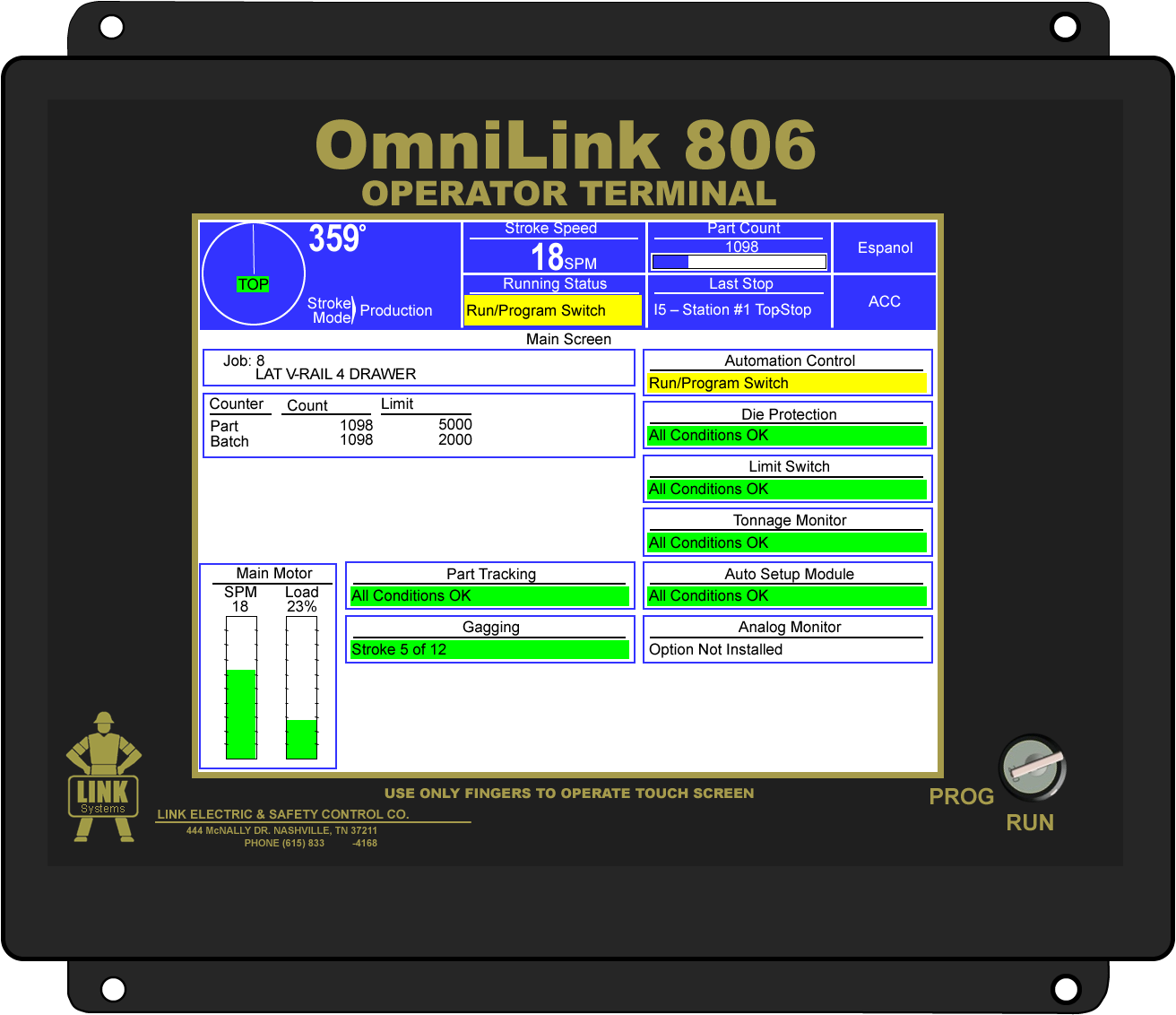

Features

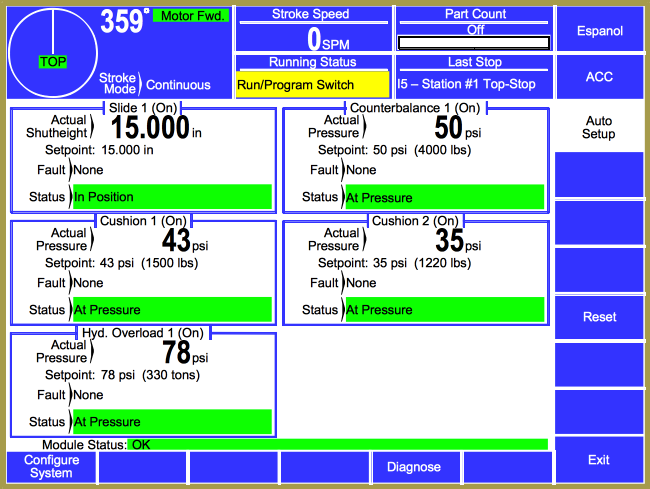

- 806 operator touch screen – English/Spanish quick select

- Resolver based crankshaft and position with graphic and numeric display

- Sets and displays stroking speed for variable speed presses

- Intelligent diagnostics

- Storage and quick recall of up to 1000 jobs

- Six – 2000 strokes/min working range

- Dual limit stopping time performance (brake) monitor

- Clutch engagement time monitor

- Automatic top stop compensation for variable speed presses

- Twelve configurable part counter groups driven by stroke or sensors that count actual parts into a bin

- Access control to prevent unauthorized changes

Optional

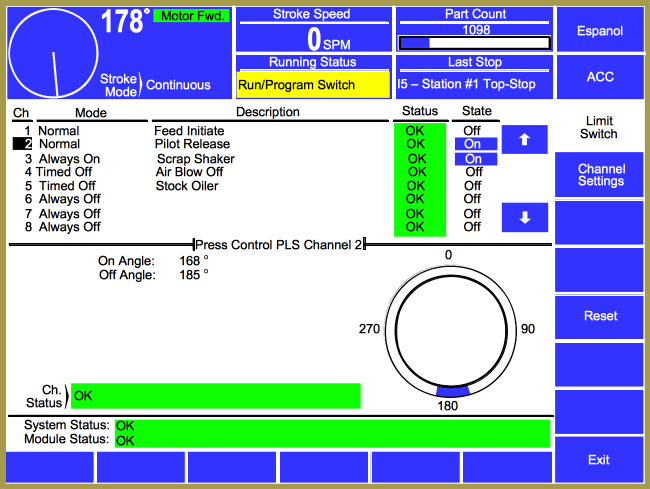

- 5100-5 Programmable Limit Switch modules provide up to 96 pls channels with tracking inputs and gagging die function capability

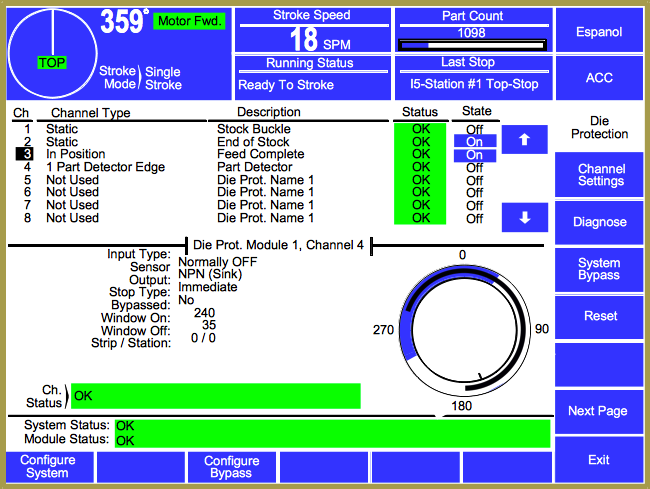

- 512x die protection modules provide up to 80 digital die protection inputs that fully integrate with gagging and part tracking

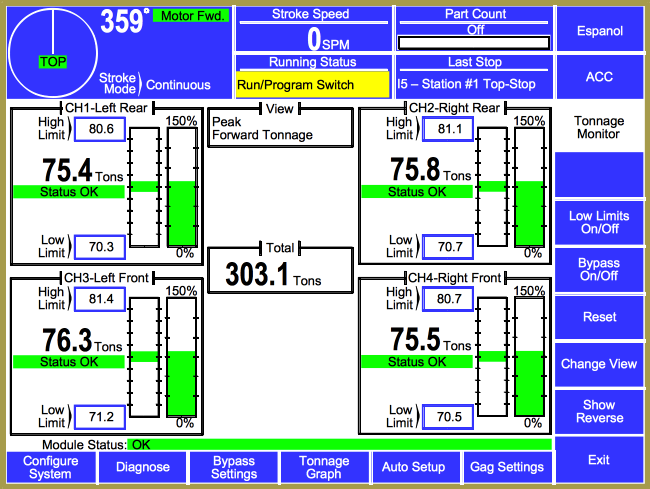

- 5100-8 Tonnage and analog signal module provides two or four channels of tonnage and signature monitoring and four general use analog channels

- 5100-14 auto setup module automatically sets press shut height and counterbalance and cushion pressures on recall for die changes

- Serial feed interface, modbus interface, and other communication options to integrate press and automation

- LinkNet 3 – shop floor data collection connection ready

- Up to four safety relay outputs for interface with automation

- Part tracking and highly-configurable gagging with sequence lengths up to 256 strokes

- Custom packaging options for modules and operator terminal

For more information on value-added features:

For more detailed specifications:

Optional Modules

Why Link

Learn More