Features

- Each channel can be programmed for use with NPN or PNP sensors

- Operates at press speeds up to 2000 spm

- Fast inputs able to catch events down to one millisecond

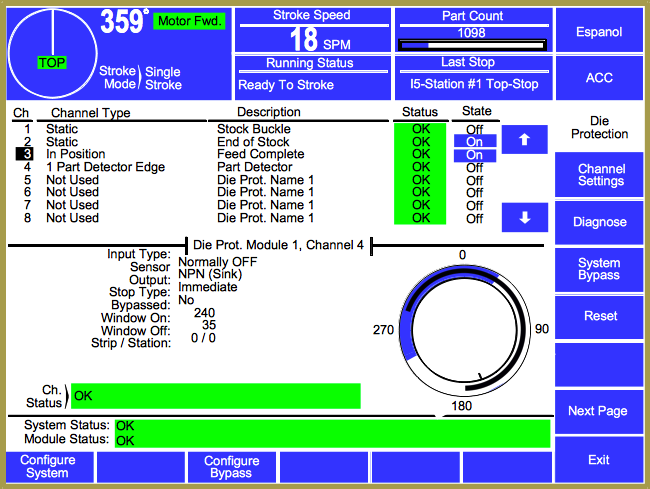

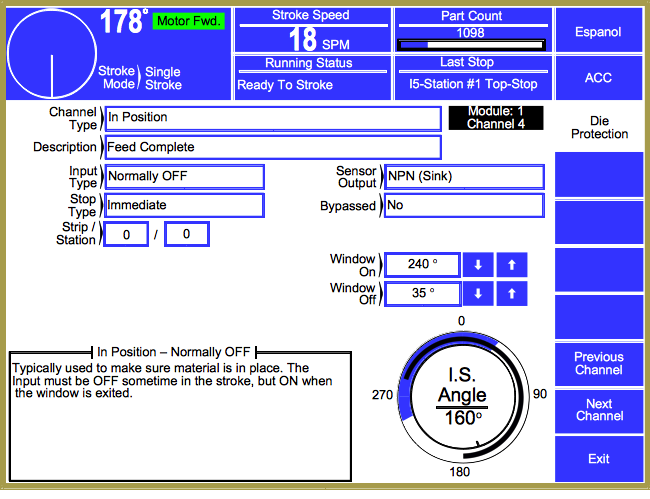

- Ten standard die protection channel logic types, plus custom types

- Each channel has its own channel logic timing window

- Channels can be configured to top stop, immediate stop, or intelli-stop

- Handles difficult situations found in the stamping environment (stuck slugs, bouncing strips, etc.)

- Channel logic for multiple-part-out situations

- Integrated gagging functionality allows easy use with lamination dies or other dies with sequencing requirements

- Supports part tracking, enabling complex applications such as automatic bad part detection and rejection

- Flexible bypassing options under supervisory control to reduce operator error and system down time

- Integrates with the system event log to report detailed information on die protection stops

- Real-time diagnostics include sensor status, voltage, in-window transitions, and more

- Real-time graphical display supports “overlaying” multiple strokes, so variations between strokes can be seen

- Supports complex servo motions when used with the 5100-amc-servo

- Each module acts as its own sensor interface connection box, and can be mounted in any convenient location for die hookups

- Front panel connection for up to eight sensors

- Internal wire terminals for up to 16 hardwired sensors

- Sensor interface provides 24 vdc @ 1 amp total

- Supports optional Link or customer-supplied quick-connect receptacle

Why Link

To help our customers meet the strict OSHA regulations in the 1980s, Link engineered innovative pressure sensing devices with our press control automation. Our innovative die protection capability prevents crashes and other conditions that can disrupt continuous production.

Learn More

Get Started Today