Features

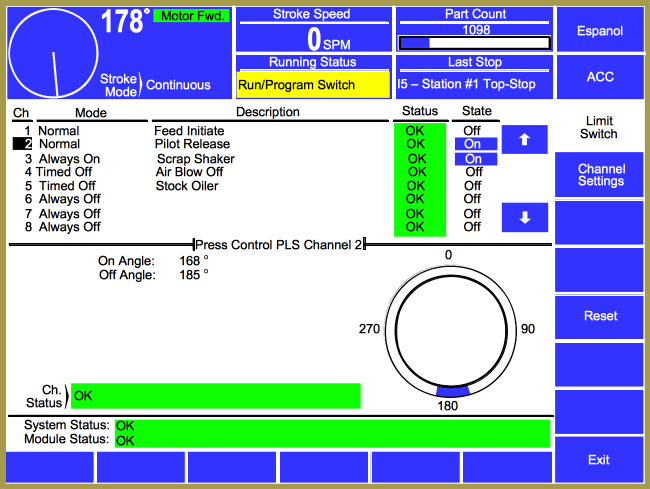

- Up to 96 PLS channels added in banks of eight

- Solid state or electromechanical outputs available

- Channels can be restricted for machine-related settings that don’t change with the job

- Flexible outputs allow sequencing of automation with press stroking, such as transfer systems, feeds, parts ejection, and other applications

- Complete diagnostics for reduced downtime

- Inputs can be used for checking the results of outputs

- Operates at speeds up to 2000 strokes per minute

- When used with the 5100-AMC-Servo, fully supports complex press cycles, including the ability to fire only on particular steps

- Speed-advanced outputs support applications with mechanical reaction times, such as feed roll release

- Supports gagging and part tracking, including when used with complex servo press cycles

For more detailed specifications:

Why Link

As the first to fully integrate tonnage monitoring, die protection, PLS, and press control into a cohesive system, Link has paved the way for metalformers to easily track all systems and functions on the press shop floor.

Learn More

Get Started Today