Features

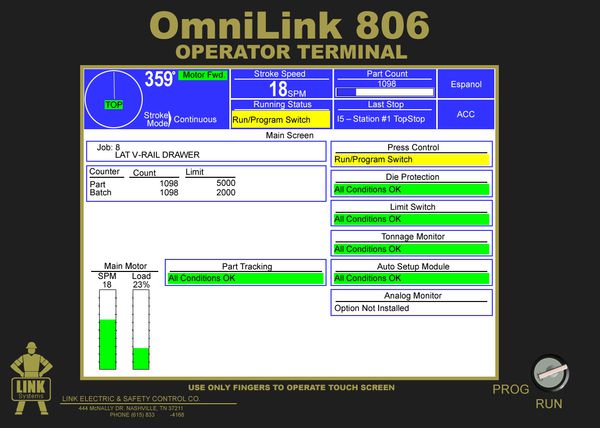

- 806 operator touch screen – English/Spanish quick select

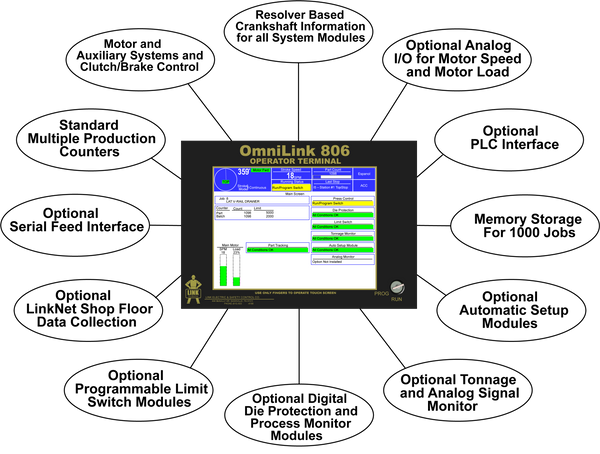

- System 5100 press control

- Intelligent diagnostics

- Storage and quick recall of up to 1000 jobs

- Six – 2000 strokes/min working range

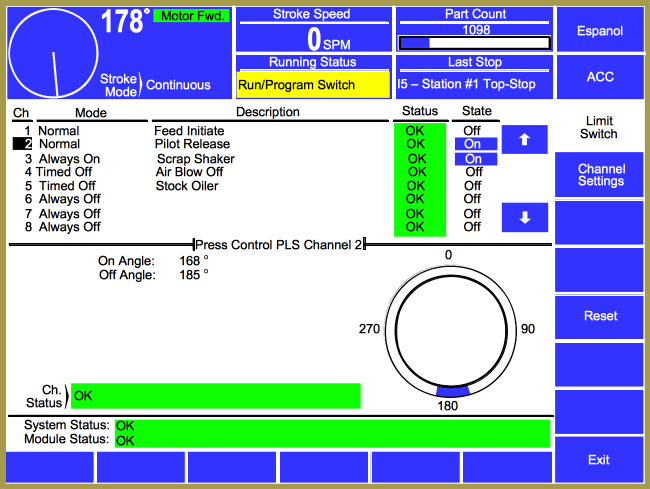

- Off, inch, automatic timed inch, setup/stop time test, single stroke, and continuous stroking modes

- Dual limit stopping time performance (brake) monitor

- Clutch engagement time monitor

- Automatic top stop compensation for variable speed presses

- Twelve configurable part counter groups driven by stroke or sensors that count actual parts into a bin

- Configurable hardware and software for a wide range of press lube systems, hydraulic overloads, and flywheel brakes

- Access control to prevent unauthorized changes

Optional

- Automatic single stroke, continuous-on-demand, and bar modes

- 5100-5 Programmable Limit Switch modules provide up to 96 pls channels with tracking inputs and gagging function capability

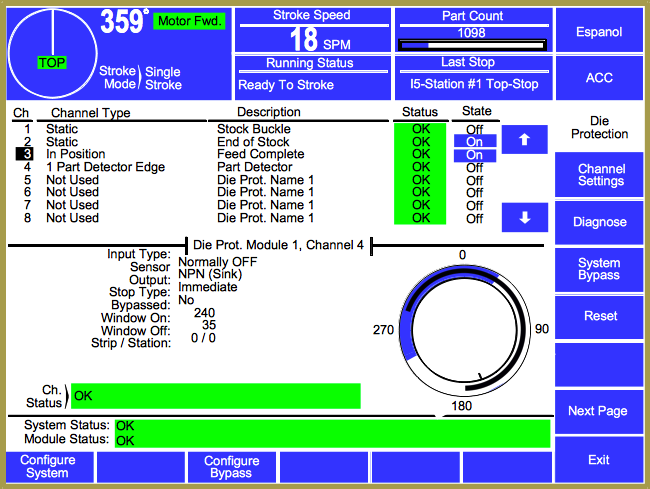

- 512X Die Protection Modules (See Below) provide up to 80 digital die protection inputs that can be integrated with gagging and part tracking

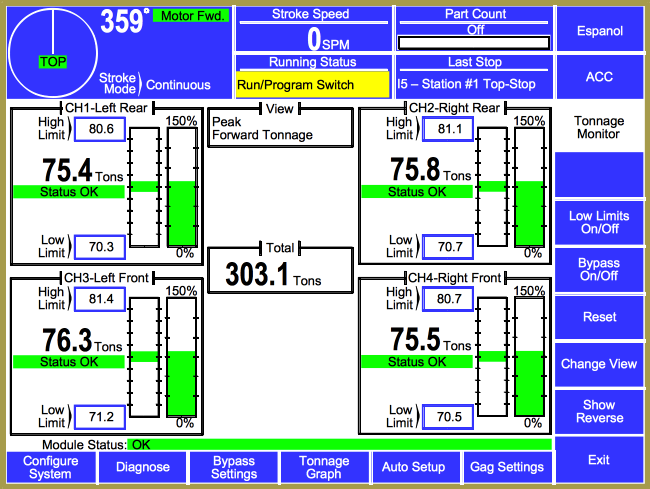

- 5100-8 Tonnage and Analog Signal Module provides two or four channels of tonnage and signature monitoring and four channels of general use analog sensing for other measurements

- Serial Feed Interface, Modbus Interface, and other communication options to integrate press and automation

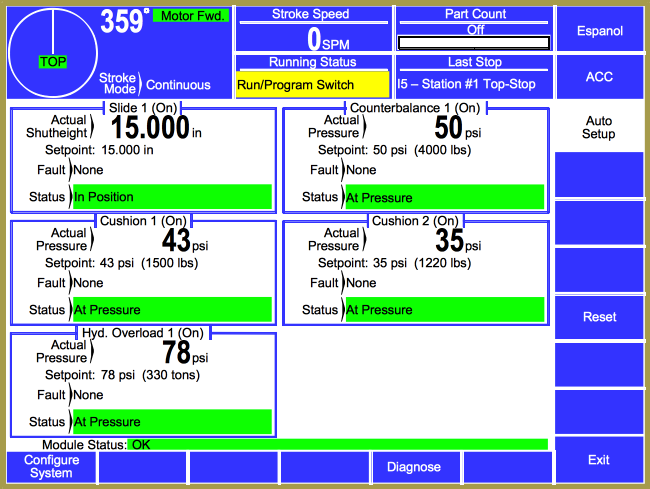

- 5100-14 Auto Setup Module automatically sets press shut height and counterbalance and cushion pressures on recall for die changes

- LinkNet 3 shop floor data collection: collects and displays data from presses and other machines on the plant floor

- Up to four safety relay outputs for interface with automation

- Up to 32 assignable function output relays

- Part tracking and highly-configurable gagging with sequence lengths up to 256 strokes

For more information on value-added features:

For more detailed specifications:

Optional Modules

Why Link

Learn More