Features

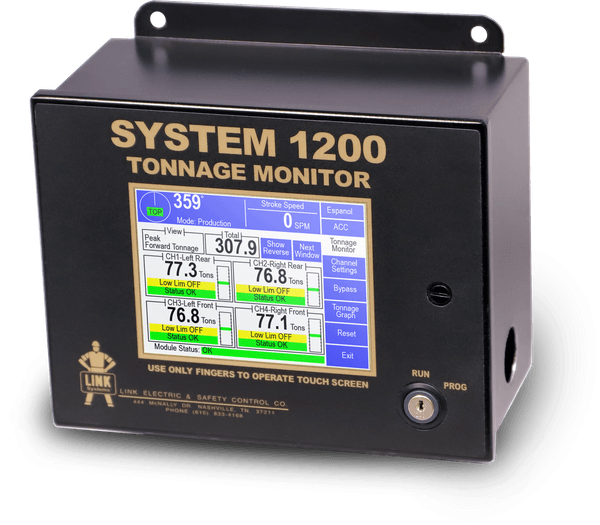

- Two or four channels for use on a variety of press frames

- Displays forward and reverse tonnage for each channel, plus the total

- Enables user to enter total capacity derating curve for distance off bottom

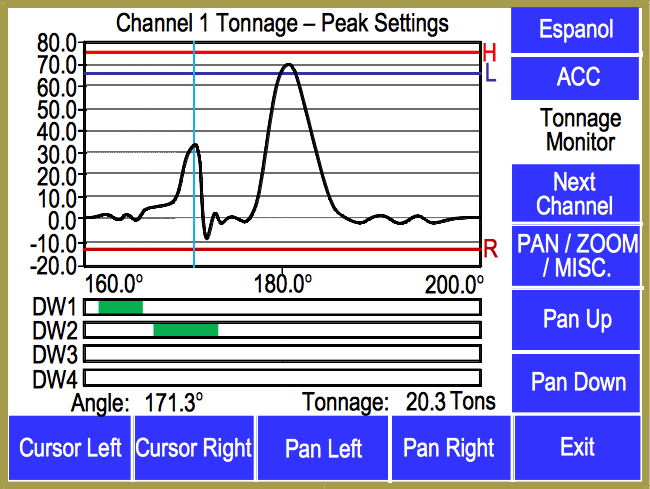

- Provides high, low, and reverse peak limits to be set for each channel

- Each channel can employ up to four additional “data window” limits for monitoring complex tonnage waveforms

- Reference graph can be stored with each job for easy comparison (with optional encoder for mechanical presses)

- Tonnage signature captured and displayed in real-time

- Signature view allows zoom, pan, and readout of angle and tonnage

- Low limits can be automatically bypassed when in setup mode

- Can be used on hydraulic and mechanical presses

- Part, batch, and quality counters can be driven by stroke or by sensors for increased accuracy

- Optional communications board with serial and ethernet interfaces for LinkNet 3, Modbus, and other functions

- Access control to prevent unauthorized changes

For more information on value-added features:

For more detailed specifications:

Optional Modules

Why Link

As the first company to successfully integrate tonnage monitoring with press controls, along with die protection and PLS, Link has paved the way for metalformers to easily track all systems and functions on the press shop floor. And because we manufacture and conduct R&D in-house, we can develop custom hardware upon request at a competitive price.

Learn More

Get Started Today