Be Done With Downtime

A press is an expensive investment. Protect it with Link's systems tonnage monitoring, and prevent excessive loads and reverse tonnage from eating into your production bottom line.

Link can engineer our tonnage monitoring systems to seamlessly integrate with your presses to help you:

- Protect Your Press From Over Tonnage Conditions

- Monitor Reverse Tonnage to Prevent Machine Damage

- Achieve Consistent Setups From Job to Job

- Analyze and Monitor Die Wear

- Monitor Up to Four Channels With Individual Tonnage Readouts, as Well as the Total Tonnage

Why Trust Link for Tonnage Monitoring

As the first to fully integrate tonnage monitoring, die protection, PLS, and press control into a cohesive system, Link has paved the way for metalformers to easily track all systems and functions on the press shop floor.

Tonnage Monitoring Products

View our tonnage monitoring options below to learn how we can engineer a highly configurable system to meet your present and future production needs.

For more detailed specifications on our tonnage monitoring products: Download Product Comparison

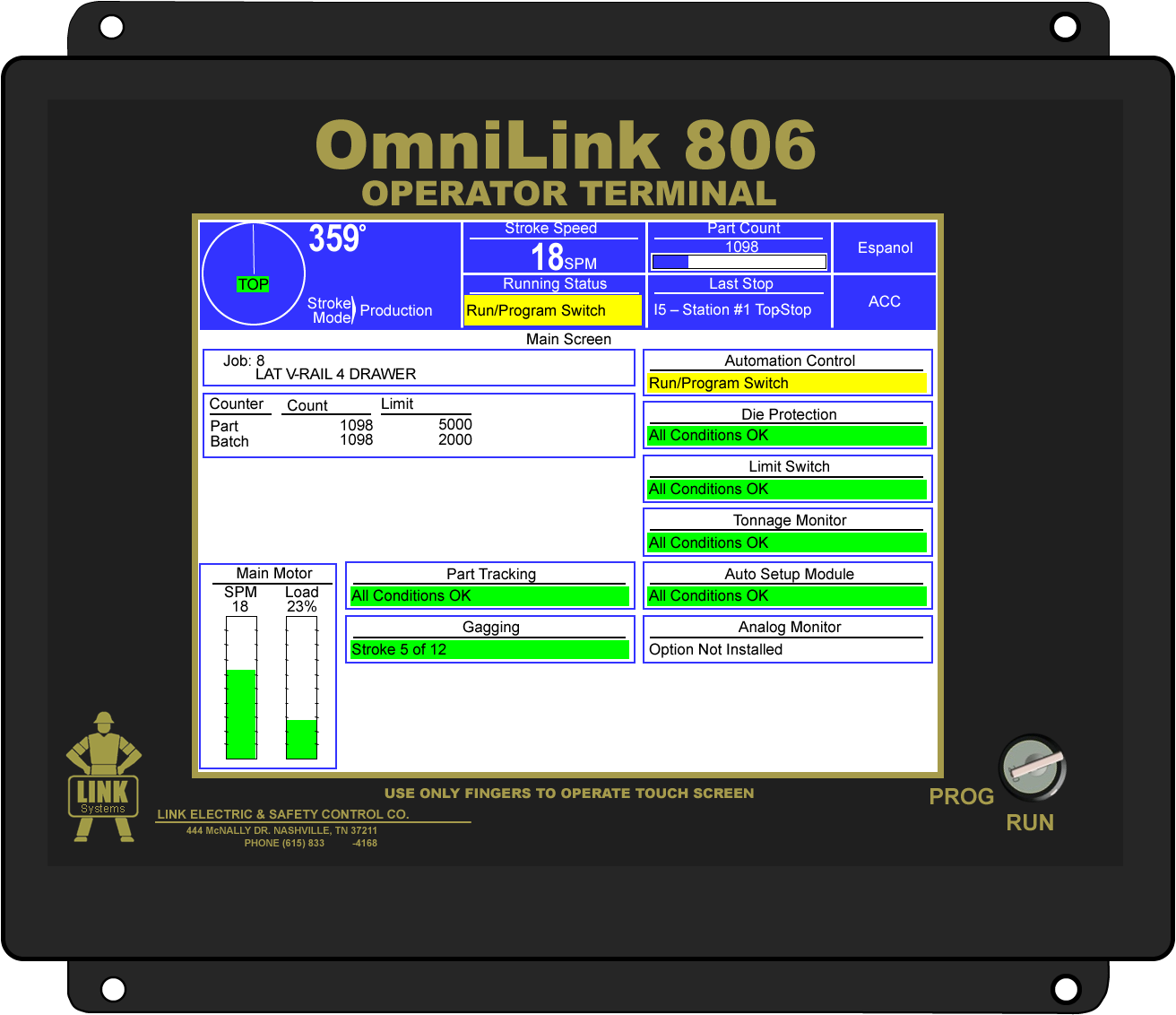

Gain ultimate press and automation control using the OmniLink 806 operator terminal to integrate the 5100 Press Control with functional modules to increase safety, productivity, and quality in your mechanical press production systems.

Learn More

Maximize press safety and productivity with a cost-effective, mechanical power press control with moderate automation capability.

Learn More

Provides complete automation control, monitoring, sequencing, and communications for part revolution mechanical power presses.

Learn More

Provides complete automation control, monitoring, sequencing, and communications for Servo presses.

Learn More

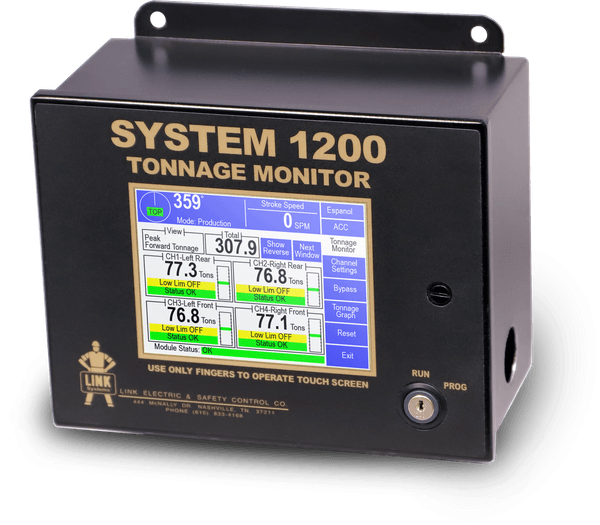

Metalformers can rely on this powerful, stand-alone tonnage monitor with data windows and signature capabilities.

Learn More