Advanced, Accurate Actuation and Sequencing

Streamline your process with Link’s advanced programmable limit switch systems. From the traditional uses of air blow-off, feed initiate, feed roll-release, and transfer interfaces to next generation applications such as no-stop bin-switching, bad part rejection, and output actuation verification via feedback inputs, Link’s got you covered.

Link’s programmable limit switch products are engineered to help you:

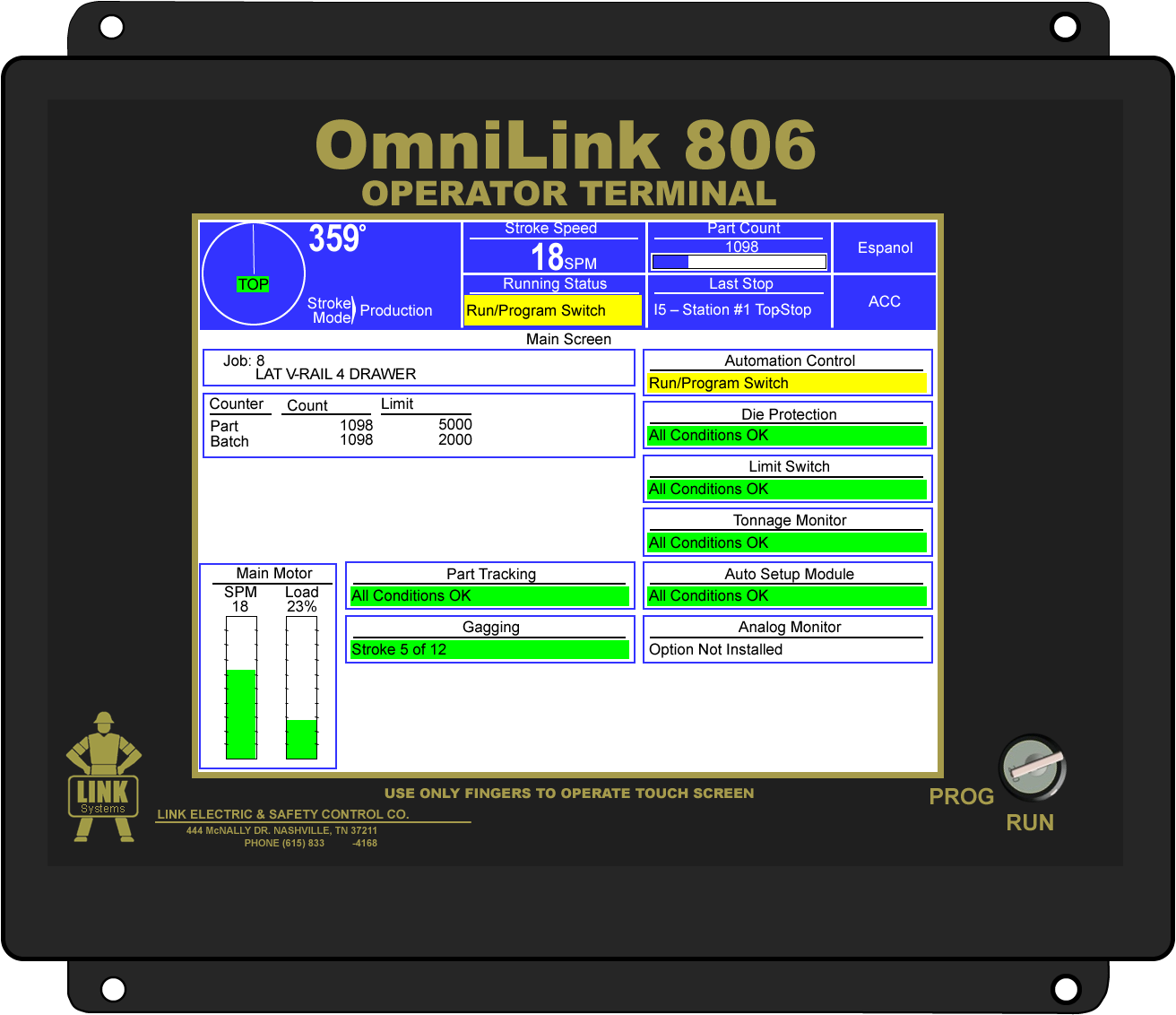

- Reduce operator training through user-friendly, multilingual, touch interface

- Ease setup through graphical depiction of pls settings

- Minimize downtime with complete diagnostics

- Individually name channels on a per-job basis

- Reduce wear and save energy by using timed outputs to control devices such as scrap conveyors that only need to run when the press is running

- Support applications with mechanical reaction times, such as feed roll release, by using speed-advanced outputs on advanced units

- Use restricted outputs to support machine-related functions that do not change with the job, such as hydraulic die clamps and hydraulic overloads

- Handle a wide variety of application loads with both electromechanical and solid state relays

Why Trust Link for Programmable Limit Switches

From standalone systems to fully integrated systems that enable unique cooperative functions, Link programmable limit switches offer performance and features second to none. Your press can last for decades, and because we manufacture all our products in-house, Link has a proven track record of supporting them for decades.

PLS Products

View our PLS options below to learn how we can engineer a highly configurable system to meet your present and future production needs.

For more detailed specifications on our Programmable Limit Switch products:

Download Product Comparison