Features

- Six supplied die protection inputs – each individually configurable on a job-by-job basis for NPN or PNP sensors, channel logic parameters, and a user-supplied description

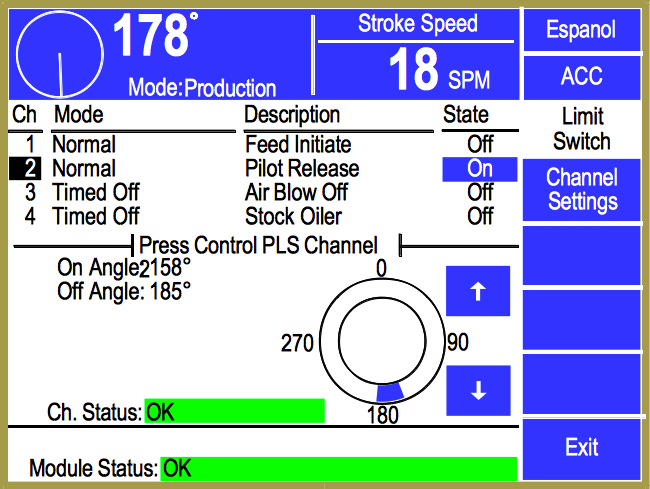

- Accommodates almost any application with 10 programmable logic types on a per-channel basis

- Handles typical situations found in the stamping environment (stuck slugs, bouncing strips, etc.)

- Part, bin, and quality counters can be driven by stroke or by sensors

- Storage for 500 jobs

- English/Spanish

- Additional auxiliary inputs easily configurable for indicating setup mode and more

- Graphical user interface provides extensive diagnostics and real-time information

- Individual sensors can be set to automatically bypass/un-bypass when in a setup mode

- Granular access control allows multiple profiles for prevention of unauthorized changes to settings

- Event log shows information on the last 250 stops for troubleshooting

- Operates at speeds up to 2000 strokes per minute

- Access control to prevent unauthorized changes

Optional

- Supports up to eight advanced pls outputs that support speed advance, toggling, timed on/off, etc., configurable on a per-channel basis

- Up to four additional programmable output relays can be installed and configured to indicate various conditions such as “crank in motion,” “bypassed,” “down time code active,” and more

- Communications card available with two serial ports and an ethernet port, which enables the use of the linknet 3 shop floor data collection system

- Modbus protocol (RTU or TCP) that can be used over serial port or ethernet port for connectivity to plc’s or data collection programs

- Serial feed interface that can display and set length, speed, and acceleration for a wide range of supported servo feeds

- Supports the use of RFID card readers or fingerprint readers for user permissions

For more detailed specifications:

Optional Modules

Why Link

As the first company to successfully integrate press controls and tonnage monitors with die boxes and PLS, Link continues to engineer these tools to solve even the toughest press automation challenges. And because we manufacture and conduct R&D in-house, we can develop custom hardware upon request at a competitive price.

Learn More

Get Started Today