Peace-of-Mind Protection for Press Productivity

From relatively minor to devastatingly major, die malfunctions can result in bad parts, extensive downtime, and costly repairs. Without sufficient die protection, your production schedule could unexpectedly grind to a halt.

Link die protection systems are designed to put the brakes on potential crashes before they occur, with:

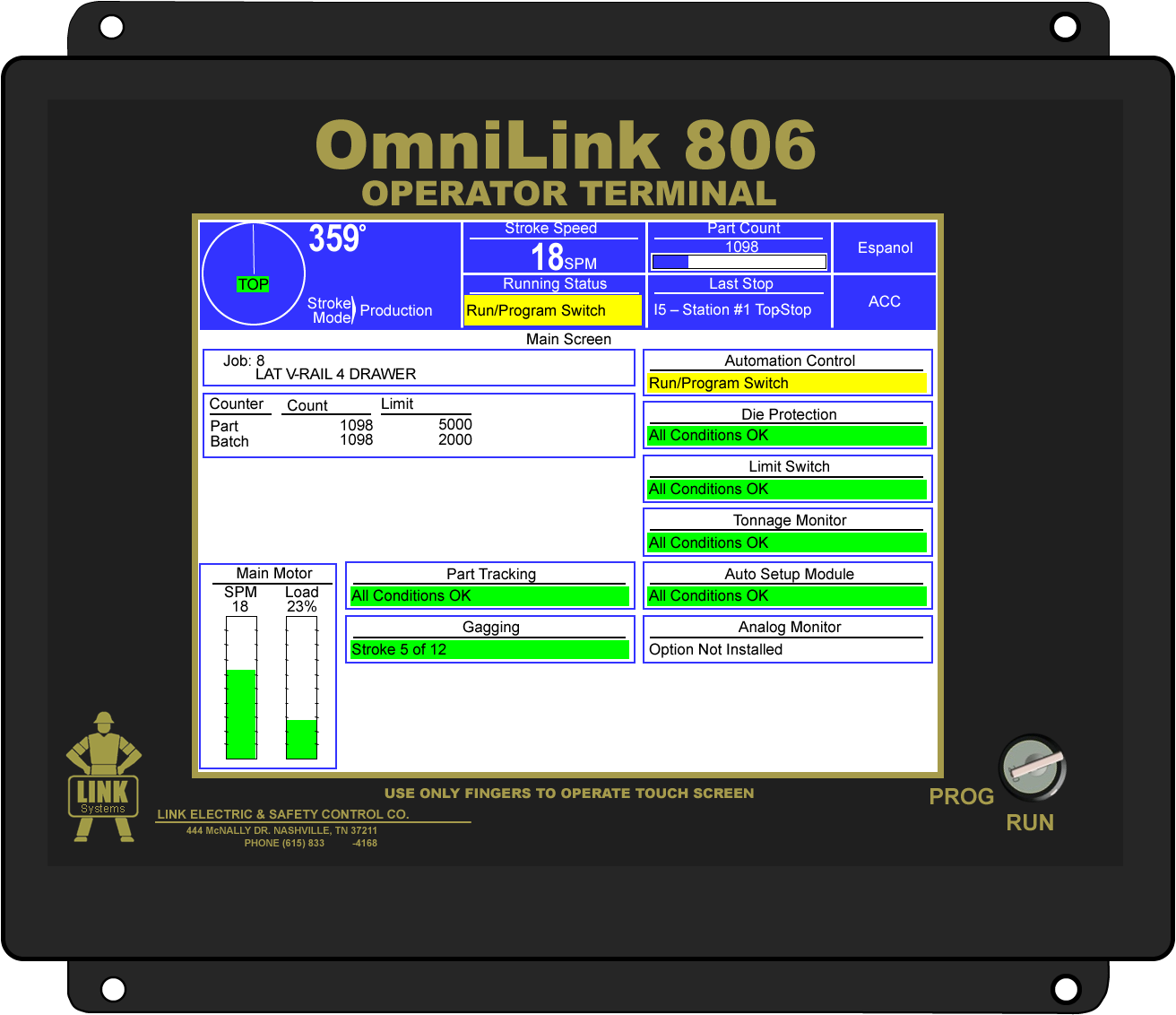

- Real-time graphical display of sensor inputs and timing windows to allow diagnostic visibility and improved ease-of-setup

- Sensors to detect misfeeds, part ejections, buckling, and other abnormal or unexpected conditions

- The ability to accommodate a wide variety of sensor types

- Multiple input types that can be programmed to meet your process requirements

- Inputs that each have their own timing window

- Die protection settings that are recalled on a per-job basis

- Configurable temporary bypassing modes to accommodate job setup and other specific situations

- Flexible supervisory control for die protection settings

- The capability to operate on presses up to 2000 strokes per minute

- The ability to report stops in a time-stamped system event log (event records the particular sensor, speed, angle, etc., that issued the stop)

- Three stop types (immediate, top or cycle, intelli-stop) assigned on a channel-by-channel basis

Why Trust Link for Die Protection

Since the early 1980s, Link has provided die protection systems geared for the real-world needs of stamping. Our engineered solutions provide reliable and flexible protection for your dies.

Die Protection Products

View our die protection options below to learn how we can engineer a highly configurable system to meet your present and future production needs.

For more detailed specifications on our die protection products:

Download Product Comparison