Get the Press Production System Experts Involved in Your Project

By involving Link during the conceptual phase of your project, we can put our extensive experience with press production systems to work for you. Every Link control is engineered for your specific application and includes detailed electrical drawings. From motor controls, servo-feeds, straighteners, transfers, robotics, and other automation on a single press to multi-press lines, we have the expertise and experience to engineer your solution.

Whether your application requires a console, mezzanine mounted enclosures, pendant arm mounted operator stations, or other configurations, our application-specific approach can handle it all. With in-house fabrication capabilities, we can accommodate nearly any control scenario.

Bring us in to survey your press and associated equipment and our engineers will work with your transfer, feed, or other automation suppliers to give you an integrated system that will make the most of your equipment.

Why Trust Link for System Integration Solutions

With over 200 combined years of control experience in the metalforming industry, our team will custom-engineer and build the right solution for your press production system, whether simple or sophisticated. Link will provide industry-leading support to ensure it brings value to your operations for years to come.

System Integration Solutions

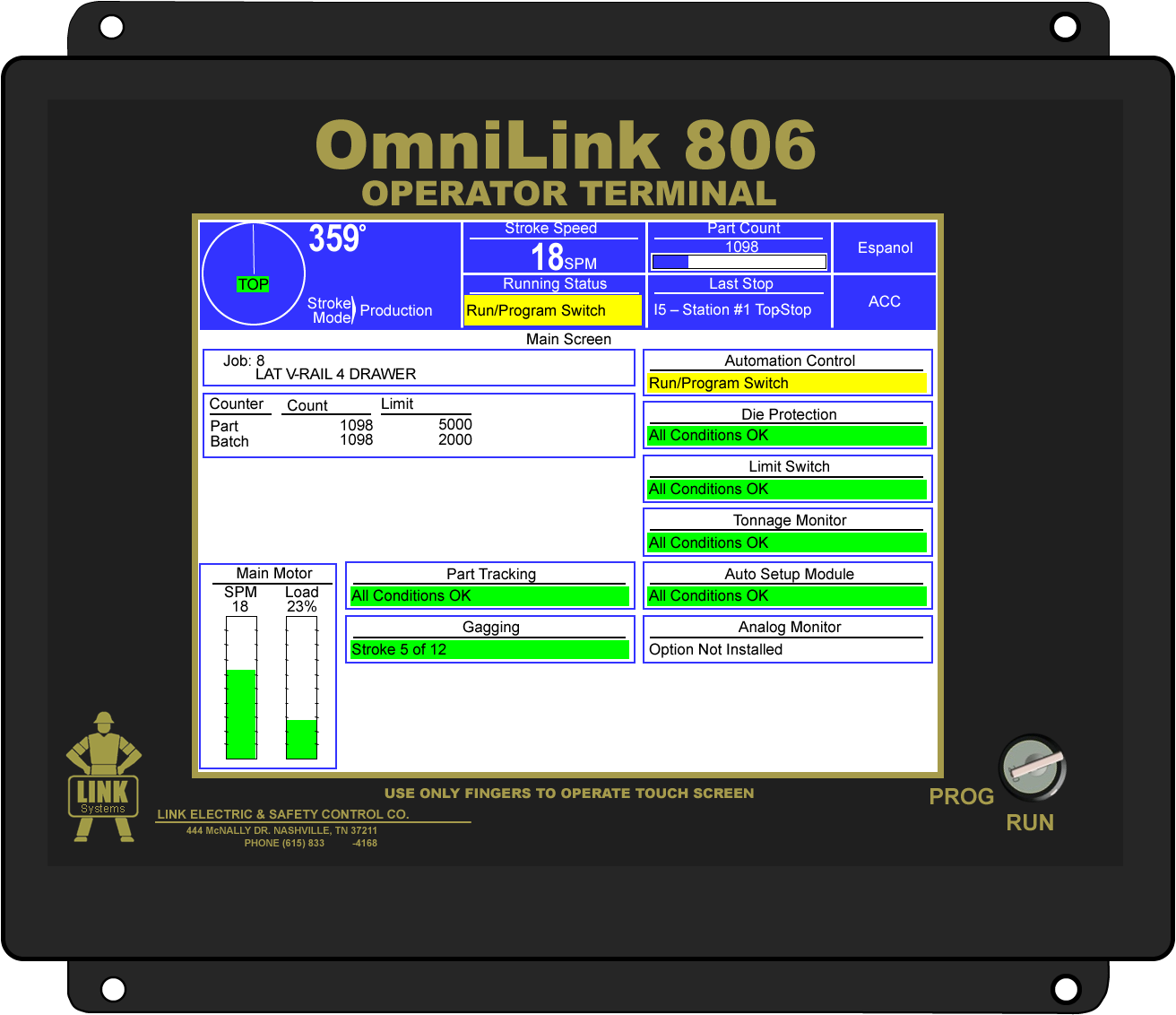

View the following for more information on the controls our system integration solutions are built upon.

For a more detailed comparison of the capabilities of our Intelligent Press and Automation Control products: Download Product Comparison