Features

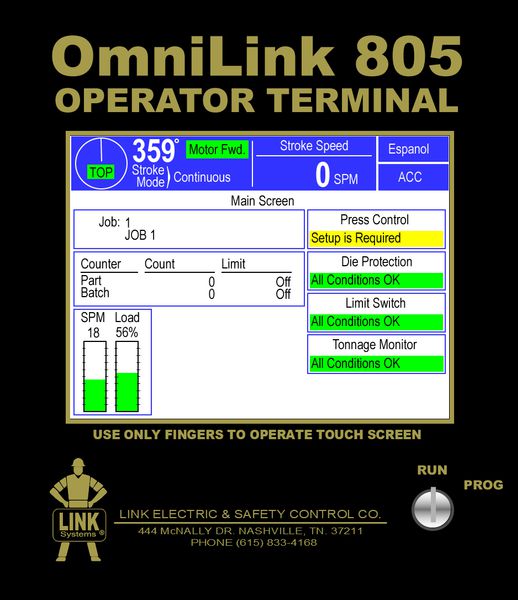

- Operator Touch Screen – English/Spanish Quick Select

- Intelligent Diagnostics

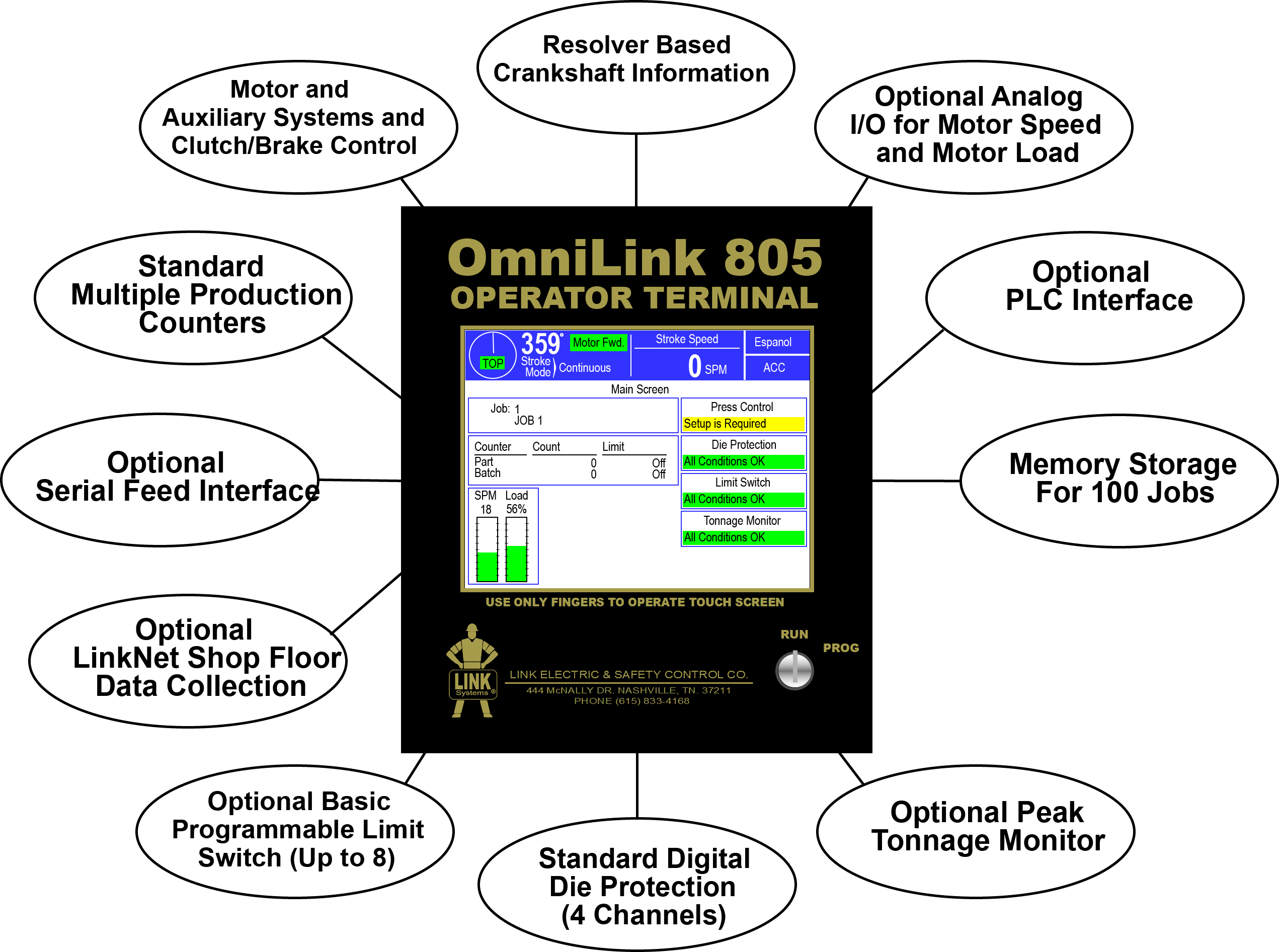

- Storage and Quick Recall of Up to 100 Jobs

- Six – 2000 Strokes/Min Working Range

- Off, Inch, Automatic Timed Inch, Setup/Stop Time Test, Single Stroke, and Continuous Stroking Modes

- Dual Limit Stopping Time Performance (Brake) Monitor

- Clutch Engagement Time Monitor

- Automatic Top Stop Compensation for Variable Speed Presses

- Two Configurable Part Counter Groups Driven by Stroke or Sensors That Can Count Actual Parts Into a Bin

- Configurable Hardware and Software for a Wide Range of Press Lube Systems, Hydraulic Overloads, and Flywheel Brakes

- Four Configurable Die Protection Inputs

- Access Control to Prevent Unauthorized Changes

Optional

- Automatic single stroke, continuous on demand, maintained continuous, micro-inch, and bar modes

- Up to 32 assignable function output relays

- Up to eight programmable limit switch outputs

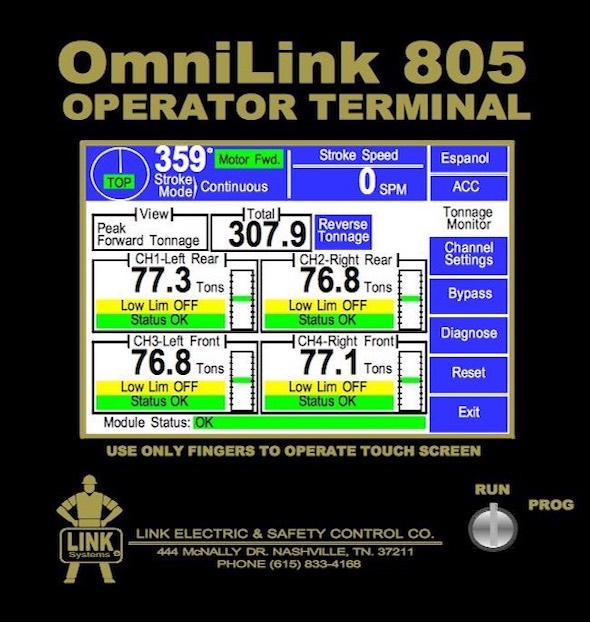

- Two or four channel peak tonnage monitor with high, low, and reverse limits

- Serial Feed Interface, Modbus Interface, and other communication options to integrate press and automation

- LinkNet 3 – Shop floor data collection connection ready

- Up to four safety output relays for interface with automation

- Large additional angle/speed displays

For more information on value-added features:

For more detailed specifications:

Optional Modules

Why Link

Learn More