Now You Can Assess Part Quality On The Fly

Analog Process Monitoring allows in-die, on-the-fly measurement of critical part dimensions to verify the quality of every part. Full integration with our part-tracking capabilities allows for automatic rejection of out-of-tolerance parts. For sophisticated dies, the system can provide feedback for automatic in-die adjustments.

Link's process monitoring systems provide features such as:

- Ability to Verify Critical Dimensions and Quality of Every Part

- Analog Sensors Enable Improved Die Protection for Very Thin Materials

- Easy Configuration

- Flexible Inputs Allow Use of Nearly Any Analog Sensor

- Tolerances and Readouts in Engineering Units (inch, mm, etc.)

- Full Process Visibility Through Angle-vs-Reading Graph for Reliable Setup and Diagnostics

- Flexible Limits Can be Configured to Provide Feedback for In-Die Adjustments

Why Trust Link for Analog Process Monitoring

With inputs and functionality specifically designed for the stamping environment, our analog process monitoring solution can help you achieve your quality goals.

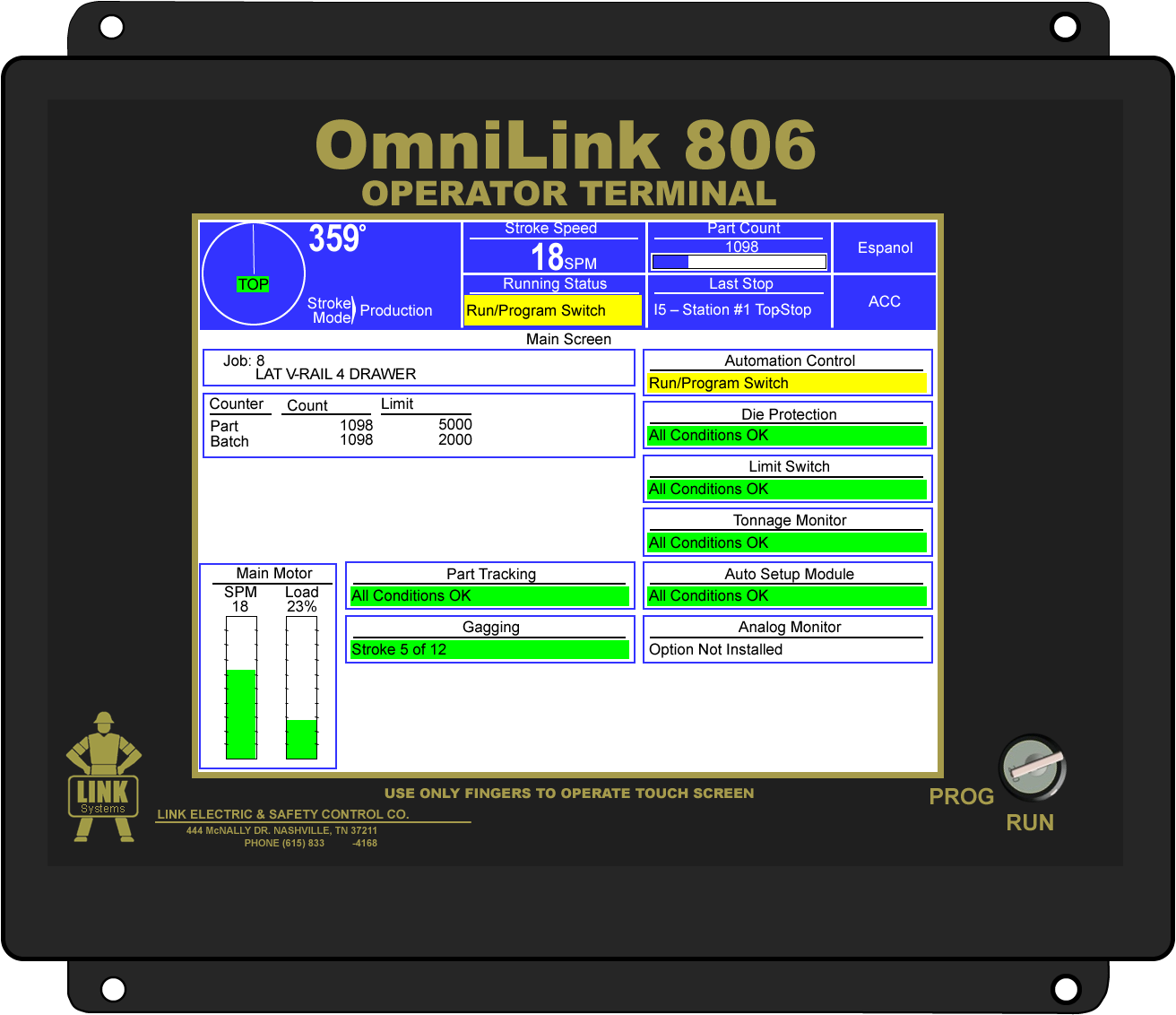

Analog Process Monitoring

View our Analog Process Monitoring offerings below to learn how we can engineer a monitoring solution to meet your present and future production needs.

For more detailed specifications on our analog process monitoring products:

Download Product Comparison