Automation Control Innovation Increases Press Efficiency for Global OEM

A global manufacturer of premium heating and air conditioning components needed an innovative solution to increase their press efficiency for metalforming clam shells for heat exchangers. Like every lean-minded OEM, they were seeking more production efficiency to expedite their products’ time to market.

The company’s efficiency conundrum consisted of multiple die stations where the clam shell components had to move through an intricate, dual press line. The press configuration consisted of two presses from different manufacturers, each with inter-press transfers, plus a separate transfer station between the two lines.

Unfortunately, the two separately-manufactured presses were different sizes, with different tonnages and stroke lengths. These presses were not designed to run in sync with each other, so the company engineers approached Link to help them find a cost-effective solution to enable both presses to stroke in lockstep to run continuously.

The Press Efficiency Challenge

Like many OEMs, they were using a typical start/stop automation process. Unfortunately, this meant each press would make a stroke, then wait for automation to signal for another stroke, make a stroke, wait for a signal, etc. This not only lowered the production rate, but also created wear and tear on the brake and clutch from repeated stopping between each stroke.

The Press Efficiency Solution

Link collaborated with this manufacturer and the press transfer company that was working on the project to identify and address technologies to allow the presses to operate in a synchronized manner.

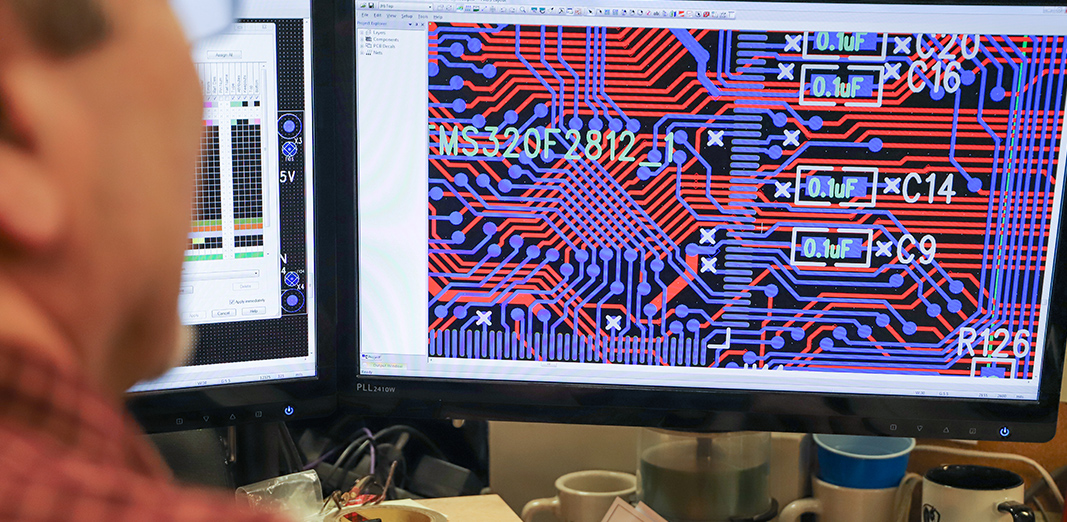

After analyzing the problem, Link engineers quickly developed a supportable, reliable solution. They took a standard operator terminal and designed a new board for it that tied into the Link controls on each press. This innovative press and automation control solution provided real-time data on angle, speed, and clutch brake status, which was used to control the drive mechanisms.

Even though the two separately-manufactured presses were different sizes with varying tonnages, stroke lengths, and drive mechanisms, Link was able to sync the presses to within plus/minus 3 degrees. The newly-engineered press and automation controls prevented miscommunications that previously caused the presses to go out of sync and stop production.

The Press ROI Results

Link enabled the presses to stay in sync to significantly reduce stoppages. Link integration with the transfer and other auxiliary equipment also gave them a new “window” into their system to see what was happening on their shop floor in real time. Link’s custom-engineered solutions helped the customer realize:

- A higher production rate

- Reduced downtime

- Less wear and tear on the presses

- Better monitoring and diagnostics

By involving Link early in identifying and addressing the problems with their press production systems, including press efficiency and downtime, the engineers were able to coordinate a complex project with multiple equipment vendors. Thanks in part to the significant ROI and efficiency improvements realized from Link’s innovative automation and press control technology, they decided to similarly retrofit additional lines.

Not only did the solution benefit this particular customer, the 805-7 Press Synchronization Module became a standard Link product and has been used in other projects.

Contact us to learn how Link can put its extensive experience in intelligent press and automation controls to work for your unique metalforming operations.